The installation of timber flooring using plywood underlay system is a method that provides solid feeling when you step on it. Plywood underlay installation method is suitable for prefinished timber flooring like engineered timber flooring and bamboo flooring. There will be some of the installer using plywood underlay for unfinished timber flooring, but is only minority in the market and we not recommend it. This installation method request both glue and nail.

Site Pre-installation:

Subfloors must be clean and free of dirt, curing compounds, sealers, drywall mud, paint, wax, grease, urethane, or other materials that may affect the integrity of the flooring material or adhesives used to install the wood flooring.

Test moisture content for concrete slab using moisture meter. The moisture content of the concrete slab should not exceed 6 percent. If it exceeds these limits, DO NOT installs the timber flooring.

Prior to installation it is necessary to ensure the subfloor conforms to level tolerance between 2mm to 3mm at 2000mm length.

Floor Board Installation:

Installation of timber flooring should not occur until other construction activities, particularly wet trades, are complete. The building/house should be roofed and enclosed with the temperature and humidity as close as possible to the expected in-service conditions.

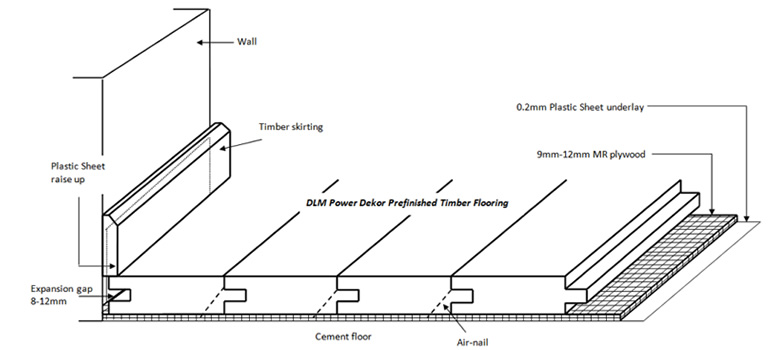

As an added protection against moisture from the slab or minor building leaks, a 0.2mm thick polyethylene membrane (plastic sheet) over the slab is recommended. The polyethylene should be lapped by 200-500 mm, taped at the joints and brought up the walls above the top of the flooring. The polyethylene is then covered by the skirting. Note that fixings of plywood underlay through the polyethylene are not considered to be an issue.

Plywood underlay should be structural grade, a 12mm (or minimum 9mm) thick. Fasten the plywood underlay on top of the plastic sheet using concrete nail and allowed an expansion gap of 8mm-12mm at all walls.

Timber floor board laid on top of the plywood underlay cover with adhesive and air-nail 45 degree direction fasten in the tongue and groove between two floors. Expansion gaps of minimum 8mm to 12mm should be provided at all walls.

Flooring Protection upon Completion:

Always protect the surface of the installed timber flooring during construction by laying a quality rosin paper or other paper that will allow the floor to breathe like corrugated paper, taping it to the baseboards. Never use plastic or polyethylene sheeting to cover the floor since they will trap moisture that will damage the flooring.